ToolDFM – A Core Technology for Mold Design and Manufacturing.

ToolDFM (Design for Manufacturability) is an essential part of mold design and manufacturing, involving a comprehensive analysis and optimization process during the product design phase. It ensures that products can be efficiently and economically produced through molding processes. The core goals are to reduce manufacturing complexity, lower costs, improve production efficiency, and enhance product quality. This work requires substantial effort and the expertise of experienced mold engineers, as DFM is a critical factor in achieving high-quality, manufacturable products.

1. Product Structure Analysis

- Wall Thickness Uniformity: Ensuring consistent wall thickness to prevent issues such as shrinkage, deformation, or stress concentration from uneven walls.

- Draft Angles: Properly designing draft angles to facilitate smooth part ejection, avoiding mold damage or sticking.

- Rib Design: Optimizing rib thickness and positioning to avoid excessive shrinkage or stress concentration caused by overly thick ribs.

2. Mold Feasibility Analysis

- Parting Line Design: Evaluating the parting line to ensure mold simplicity, ease of processing, and optimal parting.

- Slide and Core Pull Mechanisms: Designing slides or core pulls where necessary, considering their complexity and feasibility for efficient mold operation.

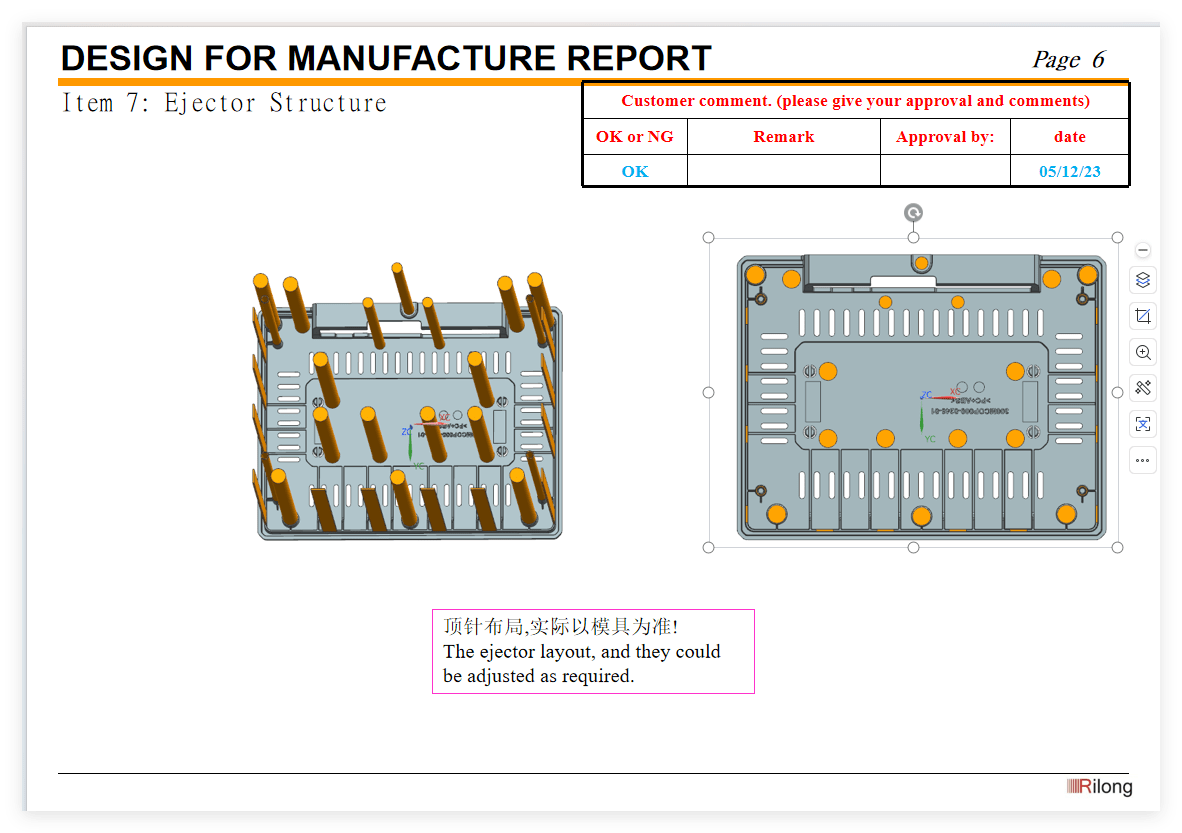

- Ejection System: Ensuring a well-designed ejection system that guarantees smooth ejection without part deformation or damage.ToolDFM (Design for Manufacturability) is an essential part of mold design and manufacturing, involving a comprehensive analysis and optimization process during the product design phase. It ensures that products can be efficiently and economically produced through molding processes. The core goals are to reduce manufacturing complexity, lower costs, improve production efficiency, and enhance product quality. This work requires substantial effort and the expertise of experienced mold engineers, as DFM is a critical factor in achieving high-quality, manufacturable products.

3. Material Selection & Molding Process Analysis

- Material Flowability: Analyzing the flowability of materials to ensure complete mold filling and correct part formation.

- Cycle Time: Assessing the impact of product design on molding cycle time, and optimizing the design to boost production efficiency.

- Shrinkage Rate: Factoring in material shrinkage to guarantee that the product dimensions align with design specifications.

4. Mold Manufacturing & Cost Analysis

- Mold Complexity: Evaluating the complexity of the mold and simplifying the design where possible to reduce manufacturing costs and processing time.

- Machining Process: Ensuring the machining processes used for mold components are efficient and precise, reducing cost and time.

- Formlebensdauer: Designing molds with durability in mind, to ensure long-term production and minimize frequent maintenance or replacement.

5. Product Appearance & Functionality Analysis

- Appearance Defects: Identifying potential appearance defects such as weld lines, shrinkage marks, or gas marks, and offering design solutions for improvement.

- Functional Check: Verifying that the design fulfills all functional requirements while being suitable for molding.

6. Assembly & Post-Processing Analysis

- Assembly Fit: Checking the compatibility of the product with other parts, ensuring easy assembly without issues due to dimensional or shape discrepancies.

- Post-Processing Requirements: Evaluating the necessity of additional post-processing steps (such as painting or plating), ensuring that the design supports these processes.

Conclusion

ToolDFM is a key part of the mold design and manufacturing process. By conducting a thorough ToolDFM analysis, companies can prevent costly mistakes, reduce manufacturing complexity, and improve both product quality and production efficiency. This process requires significant effort and the expertise of experienced mold engineers, who ensure that each mold design is optimized for manufacturability and cost-effectiveness. In the competitive manufacturing world, mastering ToolDFM can lead to more streamlined production cycles and a stronger market position.

We Engineer precision molds that define quality and performance specializing in mold design, DFM, mold flow analysis, and processing. We provide high-precision, top quality, long lifecycle molds for Medical, Automotive, Telecommunication, Security Camera, Consumer Electronics, and more. With 50+ experienced engineers and 20000+ molds produced for Fortune 500 companies, we ensure precision up to 0.005mm.